A Buyer’s Guide to Cummins Fuel Pump

Fuel pumps play an integral part in maintaining the performance and efficiency of a Cummins engine, so understanding their functions, types, selection criteria, and purchasing options are critical for making informed decisions. We explore their functions, types, selection criteria and purchasing options in this guide.

What are the Functions of Cummins Fuel Pump?

The Cummins fuel pump is a critical component of your engine’s fuel system, ensuring smooth operation and optimal performance. Its primary role is to deliver fuel from the tank to the engine at the correct pressure and flow rate. Here’s a closer look at its key functions:

- Fuel Delivery: The fuel pump ensures a consistent and reliable flow of fuel to the engine, which is essential for maintaining combustion and power output. Without proper fuel delivery, the engine may sputter, lose power, or even fail to start.

- Pressure Regulation: Modern Cummins engines, especially diesel models, require precise fuel pressure for efficient combustion. The fuel pump maintains this pressure, ensuring the injectors receive fuel at the optimal rate for performance and efficiency.

- Engine Performance: A well-functioning fuel pump directly impacts the engine’s power, responsiveness, and fuel efficiency. It ensures the engine receives the right amount of fuel under varying load conditions, from idling to heavy-duty operation.

- Emissions Control: By delivering fuel at the correct pressure and volume, the fuel pump helps achieve complete combustion, reducing harmful emissions and ensuring compliance with environmental standards.

In summary, the Cummins fuel pump is more than just a mechanical part–it’s a vital component that ensures your engine runs smoothly, efficiently, and reliably.

What are the Types of Cummins Fuel Pump?

Cummins fuel pumps come in different types, each designed to meet specific engine requirements. Understanding these variations will help you choose the right one for your needs.

Mechanical Fuel Pump

Older Cummins engines sometimes have mechanical fuel pumps. They use either a camshaft- or crankshaft-driven mechanism to carry fuel from the tank to the engine, offering dependable but less exact service than modern computerized pumps. Mechanical pumps, while inexpensive, may be enough for engines with low performance or emissions controls.

Electronic Fuel Pump

Modern Cummins engines feature electronic fuel pumps, which allow for more exact fuel delivery and pressure management. These pumps are operated by the engine’s electronic control unit (ECU), which changes fuel delivery in response to engine demand. This results in higher fuel efficiency, lower emissions, and better performance. Electronic fuel pumps are suited for contemporary diesel engines with precise fuel injection timing and pressure.

Common Rail Fuel Pump

A common rail fuel pump is a high-pressure pump used in Cummins engines equipped with a common rail fuel injection system. It delivers pressurized fuel to a shared rail, which then supplies the injectors with a consistent flow of fuel. This type of pump allows for multiple injection events per cycle, resulting in better combustion, increased power, and reduced emissions. Common rail fuel pumps are typically found in heavy-duty trucks, industrial equipment, and high-performance diesel engines.

Lift Pump (Low-Pressure Pump)

The lift pump, also known as a low-pressure fuel pump, supports the gasoline system. It is responsible for extracting fuel from the tank and delivering it to the main fuel pump. While not directly responsible for high-pressure fuel injection, the lift pump maintains a consistent fuel flow, preventing problems like fuel starvation and vapor lock. This component is critical in diesel engines since any disruption in fuel supply might lead to engine performance issues.

Each type of Cummins fuel pump serves a distinct function, and selecting the right one depends on your engine type, performance needs, and fuel delivery requirements.

How to Choose Cummins Fuel Pump Fit Your Needs?

Picking out an ideal Cummins fuel pump is crucial to ensuring that your engine operates at peak performance. Here are four key considerations, explained further:

1. Match with Your Engine Model

Not all fuel pumps are designed to work with every engine model. Incompatible pumps may lead to poor performance or engine damage. Always double-check that a pump meets your Cummins engine model number and specifications to make sure it will be compatible – older engines typically need mechanical fuel pumps while newer models might require electric or high-pressure ones; consult with an expert or refer back to its manual in order to be sure about compatibility.

2. Application and Usage Requirements

Your vehicle or equipment using a Cummins engine plays an integral part in selecting an appropriate fuel pump. Heavy-duty applications, like trucks, construction equipment or industrial machinery require robust high-performance pumps capable of withstanding constant stress and high fuel demands; lighter applications like generators or smaller vehicles may call for lighter duty pumps that meet operating conditions like temperature, load and frequency of use before making an informed choice.

3. Fuel Type and System Specifics

Cummins engines utilize different fuel types, and each comes with unique requirements. Diesel engines often need high-pressure pumps in order to meet the demands of their advanced injection systems while gasoline engines may use lower pressure pumps. Also be sure your pump matches up with your system’s specifications such as flow rate or pressure capacity so as to avoid inefficiencies or damage to its performance.

4. Quality and Reliability

For optimal long-term performance and cost savings, investing in a high-quality Cummins fuel pump is key. Choose genuine Cummins parts or reliable aftermarket brands known for durability and reliability over cheap low-quality pumps that may save upfront but end up leading to frequent failures, increased downtime, and higher repair costs down the line. Look for pumps with warranties and positive customer reviews so you’ll know you are purchasing a reliable product.

By considering these four criteria – compatibility, application, fuel type and quality- you can select a Cummins fuel pump that perfectly satisfies your needs, providing optimal performance and longevity of engine operation.

Where to Buy Cummins Fuel Pump?

Finding a reliable source for Cummins fuel pumps is crucial to ensure you get high-quality, genuine parts that meet your engine’s requirements. With so many options available, it’s important to choose a supplier that offers both quality and reliability.

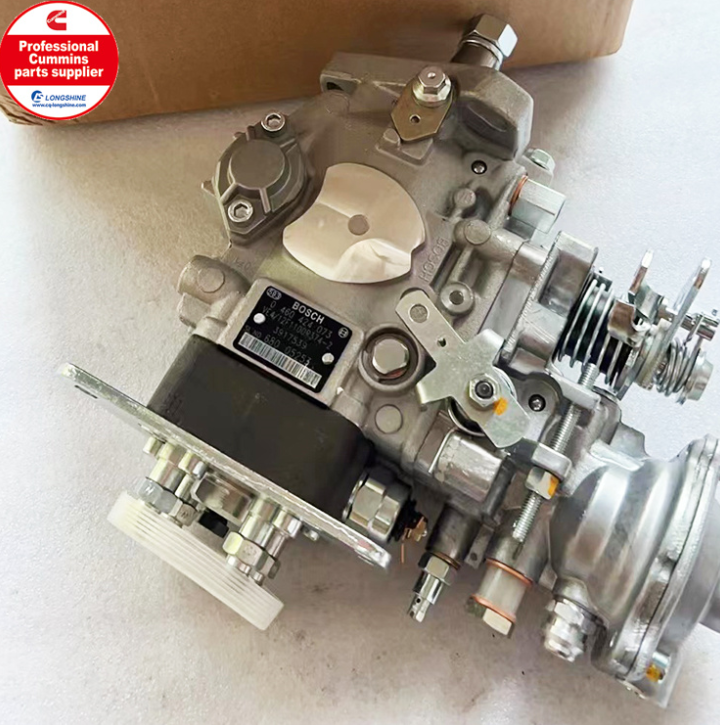

One trusted supplier is Longshine, a reputable company specializing in Cummins parts and accessories. Longshine is known for its extensive inventory of genuine and aftermarket Cummins fuel pumps, catering to a wide range of engine models and applications. Whether you’re looking for a fuel pump for a heavy-duty truck, industrial equipment, or a marine engine, we provide durable and performance-driven solutions. Their commitment to quality ensures that every part meets strict standards, giving you peace of mind and reducing the risk of downtime.

When buying a Cummins fuel pump, prioritize suppliers like Longshine that combine quality, reliability, and excellent customer service. To View more, you can visit: cq-longshine.com.